COMPRESSOR CONSTRUCTION

- Wobble Plate

- High Pressure Vapor

- From Accumulator

- To Condenser

- Low Pressure Vapor

- Piston

- Connecting Rod

ECCPP A/C COMPRESSOR FIT FOR:

- 1999-1999 BMW 318ti 1.9L

- 2000-2005 BMW 323Ci 325Ci 325xi X3 2.5L

- 1999-2005 BMW 323i 325i 525i 323is 2.5L

- 1997-2000 BMW 328i 528i 328Ci 328is 2.8L

- 2001-2006 BMW 330Ci 330i 330xi 3.0L

- 2001-2011 BMW 530i X3 3.0L

- 1997-1997 BMW 540i 4.4L

- 1998-2001 BMW 740i 4.4L

- 2001-2006 BMW M3 3.2L

- 2000-2003 BMW M5 Z8 5.0L

ECCPP A/C COMPRESSOR FEATURES:

|

|

|

|

|---|---|---|---|

Excellent Material

|

Meticulous Manufacturing

|

In-situ Installation

|

Reduce Fuel Consumption

|

COMMON FAULTS ANALYSIS:

|

|

|

|

|---|---|---|---|

1. Aging: Compressor gets aging and produces impurities, which blocks the pipes, or dry bottles become invalid, the ice causes the blockage. |

2. Pressure: Poor heat dissipation or excessive refrigerant results in high pressure, which may cause the pressure valve breakage or deformation. |

3. Leakage: The pipe assembly is installed loosely or the rubber is aging, which may cause leakage. |

4. Oil Starvation: When the system is not properly lubricated, compressor part burns out. |

|

|

|

|---|---|---|

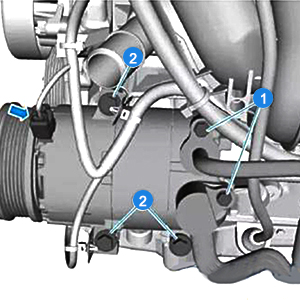

DISASSEMBLY PROCESS

|

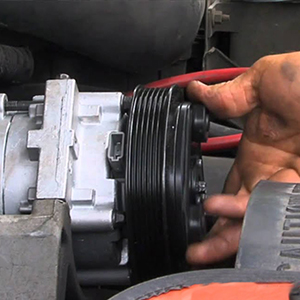

INSTALLATION PROCESS

|

INSTALLATION TIPS

|