| Product Description | |

| A sealing machine

is a type of automated assembly-line product packaging system,

commonly used in the packaging industry for food, and a wide

variety of other products. FR series continuous film sealing machines finish continuous carrying, sealing and printing in one operation. Suitable for small-bag packaging, this continuous band sealer uses an electronic constant temperature control system and a stepless speed adjusting transmission mechanism. This machine can handle various types of plastics and includes an embosser to print your expiration date, etc, save labor and improve efficiency. It can seal plastic film in various kinds of materials such as polyethylene, polypropylene & polyolefine, etc. The machine offers vertical or horizontal configuration. Horizontally model is usually used for dry food while vertical model is used from liquid sealing. This sealing machine Fr-880 is brand new with top quality. Durable and reliable, it's the best choice for you. |

|

|

|

| Specifications: | |

|

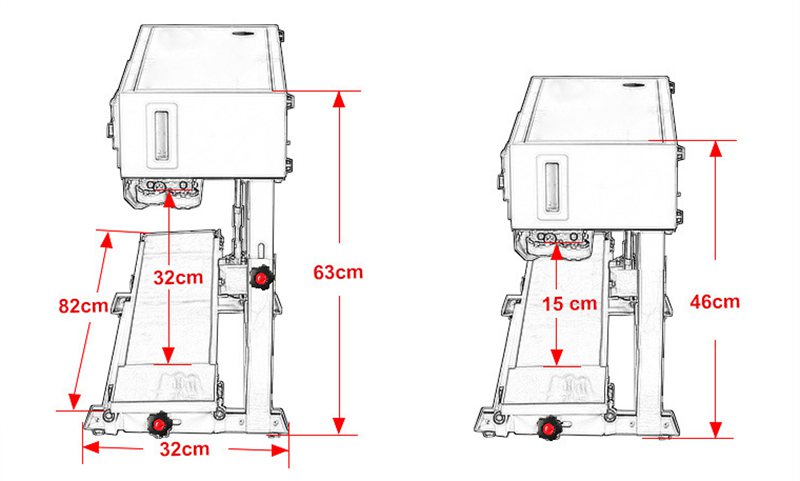

Product model: FR-880LW

Vertical Type Digital Display Machine power: 500W Motor power: 85W Power supply: 110V/60HZ Conveyor table load: ≤5kg Machine net weight: 25kg Sealing speed: ≤12m/min Sealing width: 6-12mm Temperature control range: 0-300℃ Printing method: steel stamp Sealing thickness: 0.03-0.8mm Height adjustment: 15-32cm Application: Food, Beverage, Commodity, Chemical, APPAREL Dimension(L*W*H): 850*420*360mm |

|

|

|

|

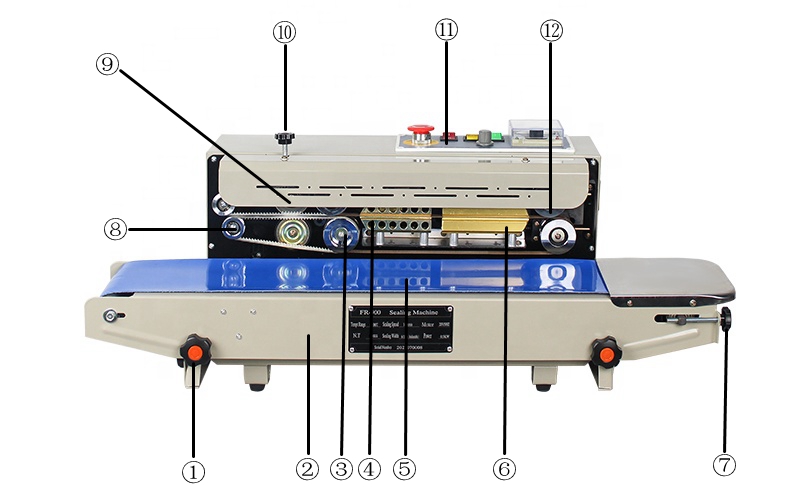

①Emergency stop ②Power switch ③Fan switch ④Heating switch ⑤Speed adjustment ⑥Digital display temperature controller ⑦Sealing width positioning frame |

|

|

|

|

①Transverse Adjustment Of Conveyor ②Conveying table ③Driving wheel ④Cooling block ⑤Conveyor belt ⑥Heating block |

⑦Conveyor Belt Adjusting Knob ⑧Guide wheel ⑨Embossing wheel ⑩Pressure Adjustment Button For Printing Wheel ⑪ Control Panel ⑫ Passive wheel |

| The machine comes with two 750mm Teflon belts for replacement, if you need more, as well as other accessories, please contact us | |

|

|

| Features: | |

|

1.Equipped with emergency stop switch, in

case of emergency, it can be shut down quickly 2.Upgrade the digital display temperature controller, clear and clear 3.Thicker body, real materials, quality assurance 4.Turbine worm gear motor, strong power and stable performance, matched with 80w copper core motor 5.A variety of lines, a variety of choices, this machine comes standard with embossing wheel and printing wheel 6.Meet the requirements of different sealing widths (can be adjusted manually) 7.Stainless steel storage table, upgraded arc design, beautiful appearance, safe to use |

|

|

|

|

|

|

|

|

|

| Parts List | |

|

|

|

1. Stainless Steel Inlet 6-12MM adjustable feed inlet, forged from stainless steel material, stable and more wear-resistant 2. Thicken Conveyor Belt It adopts thick and wear-resistant conveyor belt, which is more durable than ordinary conveyor belts for long-term continuous work and more wear-resistant. 3. Strengthen Transportation It adopts automatic conveying device, thickening active conveying wheel, passive wheel, and running more smoothly. 4. Concave Armrest There are recessed handrails on both sides of the fuselage to facilitate the movement of the machine, and the smooth edges do not hurt hands. 5. Adjustable Conveyor Table The distance between the upper and lower front and rear of the conveyor table can be adjusted, and the parameters can be adjusted according to actual needs to improve the working efficiency of the product. 6. Hollow Heat Dissipation The back side of the fuselage adopts a hollow design, which effectively ventilates and dissipates heat and extends the service life. |

|

| Items included: 1*110V Digital Display Vertical Type Continuous Sealing Machine (181287) |

|